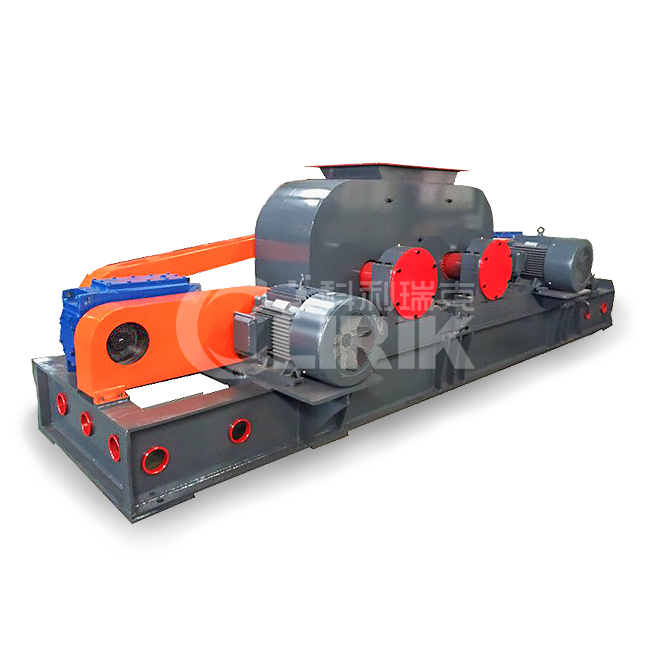

To choose the right limestone ultra-fine mill, there are several aspects that need to be emphasized. CLIRIK manufacturers will provide you with professional equipment selection and technical guidance, and match you with suitable mill models and selection schemes. If customers and friends who have limestone grinding plans do not know how to choose a special limestone grinding machine, then CLIRIK will be your ideal partner. Welcome to visit the factory to further explore the advantages of professional dry mills such as ultra-fine mills, vertical mills, and Raymond mills.

1. Inspect from limestone mill manufacturers

When selecting equipment, we must first look at the strength of the manufacturer, or whether the milling equipment developed and developed meets the development needs of the industry. With the rapid development of the ore milling machinery industry, traditional milling equipment obviously does not meet the fast-developing industry. The new generation of dry ore milling equipment has developed vigorously, which is needed to increase production, reduce noise, and reduce costs and energy-saving milling needs. Professional equipment.

CLIRIK is worthy of being a professional manufacturer of ore mills, with sufficient experience, high technology, complete types of milling equipment, and many milling cases. As long as customers give detailed milling requirements, they can customize the selection plan and match reasonable Grinding equipment and customized scientific equipment quotations will not only help you increase production, but also help you reduce overall investment costs, think about what customers think, and provide greater technical support and after-sales service for the increase of milling projects.

2. Start with the quality of limestone ultrafine mill

CLIRIK's superfine limestone mills are of good quality and guaranteed after-sales. It is also an excellent mill that CLIRIK continues to innovate. It has mechanical crushing properties such as roller compaction, milling, impact, etc., low energy consumption, good shock absorption, long service life, green and environmentally friendly equipment, dust collection rate of 99%, fine classification, good particle size, and more uniformity, which is to help fine powder The project generates benefits and realizes the environmental protection and energy saving production of the grinding machine.

3. Start with limestone mill selection and quotation

The selection scheme of each set of milling equipment is different, so the quotations are different. When customers choose limestone ultrafine mills, they need to see each set of mill selection plans and product quotations. Only mills that meet the project's milling requirements are the ideal grinding equipment. CLIRIK helps customers make one-to-one custom selection, and the matching limestone ultra-fine mill quotation is more scientific. Therefore, pre-sales CLIRIK will communicate with customers to obtain information on the project details, capacity and other information in a timely manner, so as to customize solutions and product quotations for customers.

When purchasing a limestone superfine mill, you must look at the details of the manufacturer’s strength, the quality of the superfine mill for grinding fine powder, the manufacturer’s after-sales service, and the selection of the entire production line. CLIRIK is your trustworthy mill. Flour mill manufacturers, welcome to our factory to learn more about the 200-3000 mesh ultra-fine pulverizer equipment. If there is a need, call the 24-hour online hotline for details, we sincerely invite you to visit: +8613512155195/+8613917147829