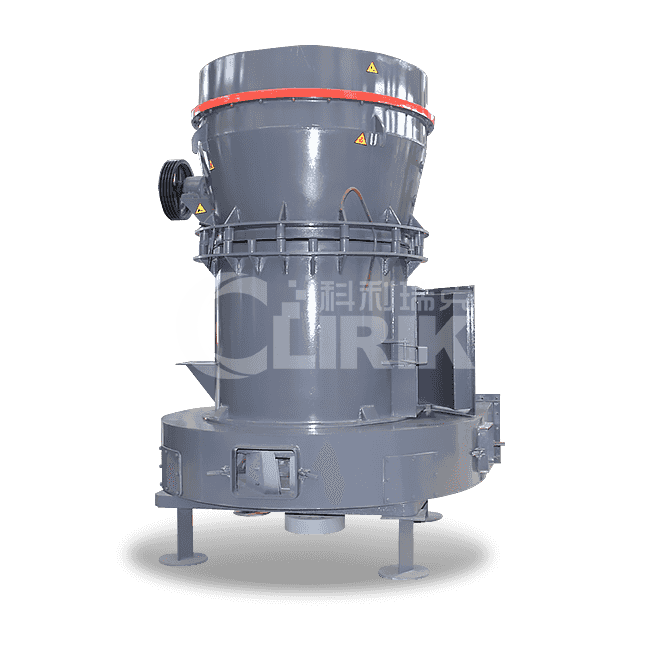

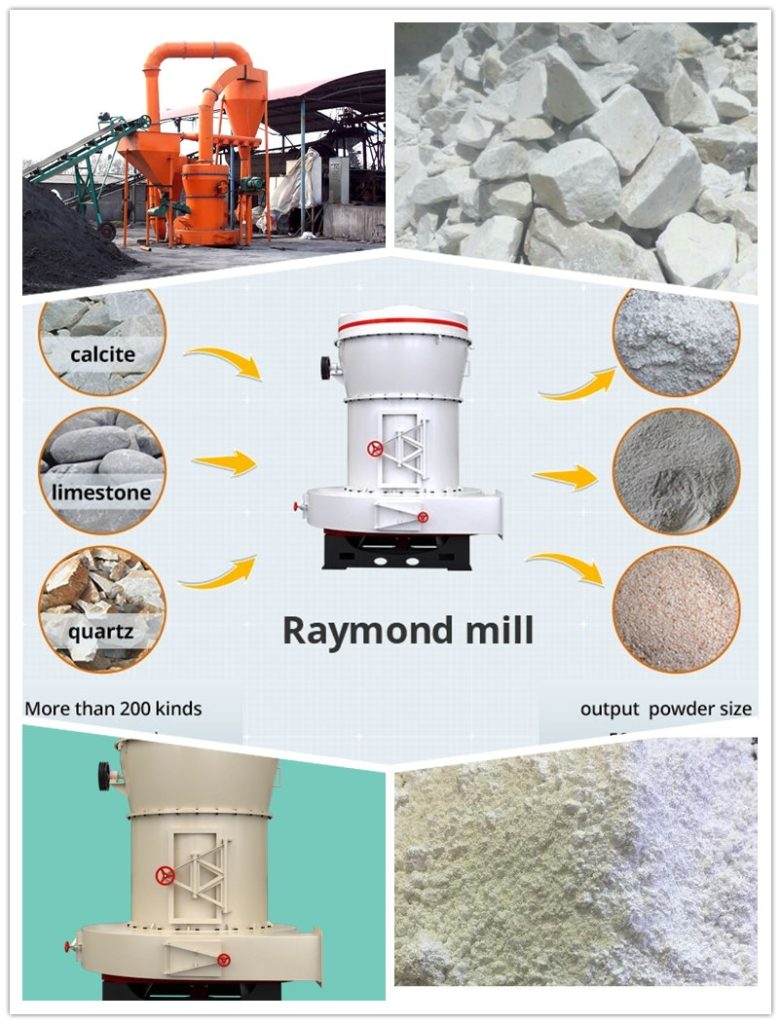

YGM Raymond roller grinding mill is mainly suitable for grinding and processing metallurgy, building materials, chemical industry, mining, and other mineral products.

YGM Raymond roller grinding mill has many names in the industry, such as Raymond mill, pulverizer, YGM Raymond mill, 3R grinding mill, 4R mill, 5R mill, etc.

Application range: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, non-metallic ore pulverizing, coal powder preparation, etc.

Material: quartz, feldspar, calcite, talc, barite, fluorite, rare earth, marble, etc.

Capacity: 1.5-40t/h

Finished fineness: 80-600 mesh

Features

Features

Raymond mill is mainly suitable for grinding and processing metallurgy, building materials, chemical industry, mining, and other mineral products.

Raymond mill can grind quartz, feldspar, calcite, talc, barite, fluorite, rare earth, marble, ceramics, aluminum Vanadium soil, manganese ore, iron ore, copper ore, phosphate rock, red iron oxide, zircon sand, slag, water slag, cement clinker, activated carbon, granite, garnet, yellow iron oxide, bean cake, fertilizer, compound fertilizer, fly ash, bituminous coal, coking coal, lignite, limestone, chrome oxide green, gold ore, red mud, clay, kaolin, coke, coal gangue, china clay, kyanite, fluorspar, bentonite, medical stone rhyolite, Pyrophyllite, shale, purple sandstone, green mudstone, stacked rock, basalt, gypsum, graphite, silicon carbide, thermal insulation, materials and other non-flammable and explosive materials with Mohs hardness below 6 and humidity of 6% Processing of mineral materials.

Raymond Roller Mill

Performance Advantage

Performance Advantage

- 1. Energy efficientUnder the condition of the same finished product fineness and motor power, the output is more than double that of jet mill, stirring mill and ball mill.

- 2. Long service life of wearing partsGrinding rollers and grinding rings are forged with special materials, which greatly improves the utilization. Generally, it can last for more than one year. When processing calcium carbonate and calcite, the service life can reach 2-5 years.

- 3. High safety and reliabilityBecause there is no rolling bearing and no screw in the grinding chamber, there is no problem that the bearing and its seals are easily damaged, and there is no problem that the screw is easy to loosen and damage the machine.

- 4. Environmentally friendly and cleanThe pulse dust collector is used to capture dust, and the muffler is used to reduce noise, which is environmentally friendly and clean.

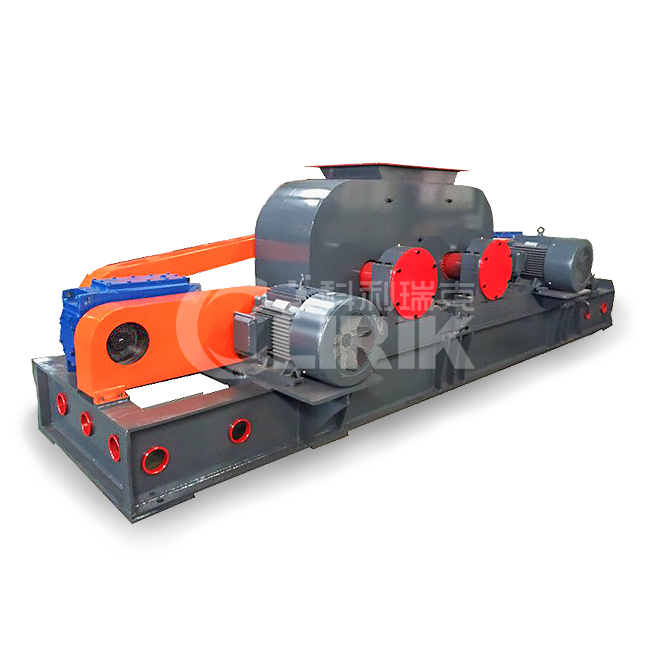

Structure and Composition of YGM Raymond Roller Grinding Mill

Structure and Composition of YGM Raymond Roller Grinding Mill

The complete equipment of Raymond mill consists of main engine, reducer, analyzer, piping device, blower, dust collector, jaw crusher, bucket elevator, electromagnetic vibrating feeder, electric control system, etc.

Matters needing attention in the work of Raymond mill

Matters needing attention in the work of Raymond mill

1. During using Raymond roller mill, professional staff should take care of it. Equipment operators must have a certain relevant technical level. Before the mill is installed, the operator must have the necessary technical training, so that they can understand the principle and performance of the mill, and be familiar with the operating procedures, so as not to be unable to solve the problem in time.

2. In order to make the pulverizer work normally, relevant safety operation instructions should be formulated to ensure the long-term safe operation of the equipment. At the same time, the equipment should be equipped with necessary maintenance tools, grease and corresponding accessories.

3. During the use of the pulverizer, regular maintenance should be carried out. At the same time, it is necessary to pay attention to the maintenance of the wearing parts such as the grinding roller, grinding ring, blade, etc. If it is worn, it should be replaced immediately to avoid greater damage.

Working Principle

Working Principle

The working principle of Raymond mill:

In the Raymond mill, a Raymond spring with a pressure of 1 000-1 500 kg is fastened on the roller hanger. After starting to work, the grinding roller rotates around the main shaft and rolls close to the grinding ring under the action of Raymond spring and centrifugal force. Its rolling pressure is 20% higher than that of the Raymond mill under the same power condition, so the output is greatly improved.

When the material to be ground enters the grinding chamber, it is shoveled by the shovel and sent to the grinding roller and the grinding ring for rolling. The powder after rolling is brought into the analyzer with the circulating air of the blower, and the qualified fine powder flows into the cyclone collector with the airflow. The powder device is the finished product, and the large particles are reground behind. The circulating air returns to the blower to repeat the above process, and the residual air enters the bag filter.

When the grinding roller and the grinding ring reach a certain level of wear, adjust the length of the Raymond spring to maintain a constant grinding pressure between the grinding roller and the grinding ring, so as to ensure stable output and fineness.

Technical Parameter

Technical Parameter

| Model | Grinding Cavity Diameter (mm) | Feed Particle Size (mm) | Finished Product Fineness (mesh) | Installed Power (kw) | Output (t/h) | Appearance (L*W*H/mm) |

|---|---|---|---|---|---|---|

| YGM9720 | 970 | 20 | 80-600 | 97 | 1.5-7.5 | 8200*6010*7200 |

| YGM1280 | 1280 | 20 | 80-600 | 145 | 2-10 | 8500*7500*8200 |

| YGM1300 | 1300 | 20 | 80-400 | 222 | 2-14 | 10100*9300*8330 |

| YGM1620 | 1620 | 30 | 80-400 | 322 | 2.5-18 | 10250*8090*10510 |

| YGM1720 | 1720 | 35 | 80-325 | 442 | 6-30 | 12500*12250*10400 |

| YGM2150 | 2150 | 35 | 80-325 | 572 | 12-40 | 12000*11600*11000 |

Note: This capacity range is based on domestic calcium carbonate materials, and the differences between different materials will vary.