The hardness of

talc is very low and and there is no difficulty in processing it, so a

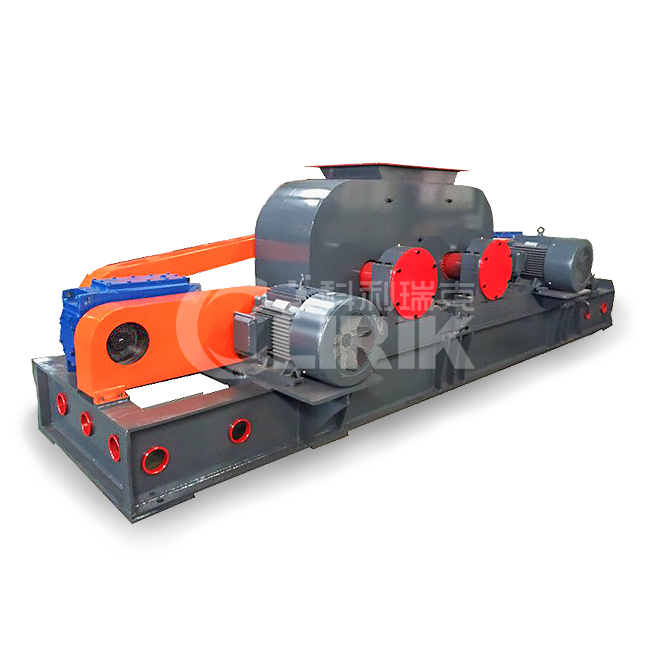

talc powder production line can be processed by general grinding equipment. CLIRIK's milling equipment includes:

high-pressure grinding mills,

ultrafine grinding mills,

superfine powder mills,

vertical mills, etc., and we will recommend and provide suitable solutions and grinding plant equipment according to the different needs of users.

1. What is talc?

Talc is a common silicate mineral, it is very soft and has a creamy feel. People have selected 10 minerals to represent 10 hardness levels, called Mohs hardness. Among these 10 levels, the first (that is, the softest one) is talc. Soft talc can replace chalk to draw white marks. Talc is generally lump, leaf, fibrous or radial. The color is white, off-white, and it will have various colors due to other impurities. Talc has many uses, such as refractory materials, papermaking, rubber fillers, pesticide absorbents, leather coatings, cosmetic materials, and engraving materials.

2. What does the cost of the talc production line include?

The production cost of the talc processing line depends on your product requirements and output. If mining is not included, just crushing and selling raw ore, the cost is low. Just configure a production line. If you need to sell at a high price and you need to beneficiate, the cost is high and the profit is high. First determine your sales direction and do market research before purchasing equipment.

3. Talc powder mill

Today, with the vigorous development of mining machinery, pulverizers have been widely used, and talc, as one of the ore, cannot be separated from the grinding process of pulverizers. Shanghai Clirik Machinery Co., Ltd. produces various types of mining equipment with strong processing capacity, stable performance, uniform and adjustable powder output, and is an excellent equipment for grinding talc.

Talc is usually processed into talc powder, the talc after repeated crushing by a crusher, and then processed by a milling machine can be used in many fields. Talc fine powder is the upstream and original material for most industrial manufacturing, covering almost all the production and manufacturing departments of light and heavy industries.

The hardness of talc is very low and and there is no difficulty in processing it, so a talc powder production line can be processed by general grinding equipment. CLIRIK's milling equipment includes: high-pressure grinding mills, Raymond mills, ultrafine grinding mills, superfine powder mills, vertical mills, etc., and we will recommend and provide suitable solutions and grinding plant equipment according to the different needs of users.

4. Talc beneficiation production line

The talc beneficiation production line is a production line with flow-through production capacity designed for the industrial industry for talc processing and processing. It consists of four stages: crushing, grinding, screening, and separation. After processing, talc minerals can be processed into three different beneficiaries. Products: ferrous trioxide, ferrous sulfate solution and talc fine powder. If necessary, subsequent manufacturers can add other equipment to process ferrous oxide and ferrous sulfate solution to obtain ferroferric oxide and other products. Here we are talc beneficiation mainly to obtain talc fine powder, so the plan configuration introduced in the follow-up is mainly to obtain talc fine powder, and other processes can be redesigned by the manufacturer according to user needs.

5. Guide to Buying Talc Grinding Plant

When purchasing a talc production line, you must look at the details of the manufacturer's strength, product quality, after-sales service of the manufacturer, and selection of the entire production line. CLIRIK is your trusted talc production line supplier. Welcome to contact us for more information.

Contact number: +86-13512155195 (WhatsApp)

Email: sales@clirik.com

The hardness of talc is not great, and there is no difficulty in processing it, so it can be processed by general grinding equipment. CLIRIK's milling equipment includes: high-pressure mills, ultra-fine mills, ultra-fine mills, vertical mills, etc., and we will recommend and provide suitable solutions and milling production line equipment according to the different needs of users.