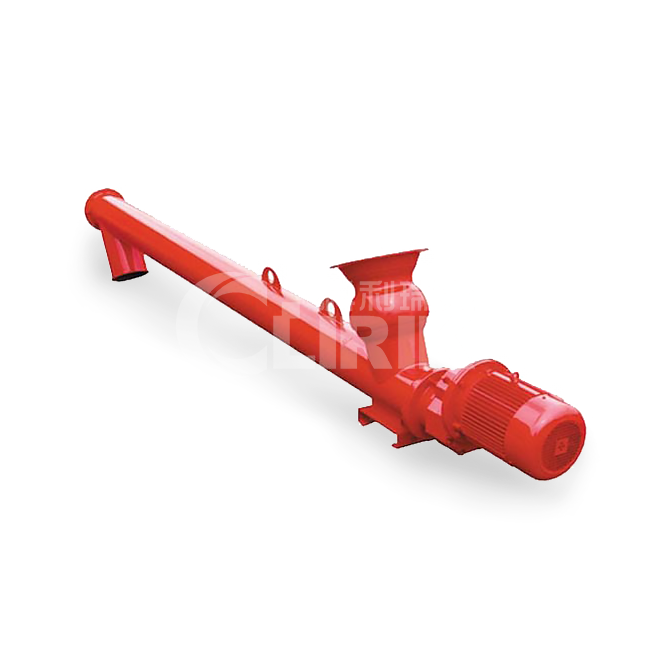

Screw conveyor is a widely used conveying equipment in mining and construction industries. From the perspective of the displacement direction of conveying materials, screw conveyors are divided into two categories: horizontal screw conveyors and vertical screw conveyors.

Scope of application: suitable for conveying powder, granular and small lumps of non-abrasive and low-abrasive materials, such as coal, cement, stone, sand, clay, ores, etc.

Material: coal, cement, stone, sand, clay, ore, etc.

Equipment speed: 70-90r/min

Conveying capacity: 2-110m³/s

Features of screw conveyor

Screw conveyor is a widely used conveying equipment in mining and construction industries. From the perspective of the displacement direction of conveying materials, screw conveyors are divided into two categories: horizontal screw conveyors and vertical screw conveyors.

vertical screw conveyors

Screw conveyors

Horizontal screw conveyors

Screw conveyors are mainly Horizontal and vertical conveying of various powder, granular and small pieces of loose materials. The rotating speed of the screw body of the vertical screw conveyor is higher than that of the ordinary screw conveyor. Under the action of centrifugal force, the added material generates frictional force with the casing, which prevents the material from rotating with the screw blade and overcomes the falling of the material. The gravity of the material thus realizes the vertical conveying of the material.

The conveying capacity of the machine is small, the conveying height is small, the rotation speed is high, and the energy consumption is large. It is especially suitable for conveying powder and granular materials with good fluidity. It is mainly used for lifting materials, and the lifting height can generally reach 20 meters.

The horizontal screw conveyor is convenient for multi-point loading and unloading, and the mixing, stirring or cooling functions can be completed at the same time during the conveying process.

It is sensitive to overload and easy to block; it has crushing loss to materials. The structure of the horizontal screw conveyor is simple, which is convenient for installation, maintenance and troubleshooting. The conveying length can also reach 150 meters.

The performance characteristics of screw conveyor

- 1. Small section size, good sealing performance, reliable operation and low manufacturing cost.

- 2. For intermediate loading and unloading, the conveying direction can be reversed or conveyed in opposite directions at the same time.

- 3. During the process, the materials can also be stirred, mixed, heated and cooled.

- 4. The loading and unloading gate can adjust the material flow, and it is not suitable to transport materials that are perishable, viscous, easy to agglomerate and bulky.

- 5. The tightness and proper clearance between the screw and the trough can prevent the material from being easily broken and the screw and the trough from being worn during the conveying process.

The composition of the screw conveyor

The screw conveyor usually consists of three parts: the screw conveyor body, the in-out device and the drive device. The screw machine body is composed of three parts: the head section, the middle section and the tail section.

Matters needing attention in the work of screw conveyor

- 1. Add lubricating oil to transmission parts such as bearings, gears and chains.

- 2. After use, check the wear of the spiral blades, and repair the welding when the wear is serious.

- 3. Overload, otherwise the material will not be discharged, which will cause the bending of the screw shaft and the expansion of the box.

- 4. When the quality is high, you should pay attention to whether the expansion and contraction of the box is free and there is no stuck place. If there is, it should be solved quickly.

- 5. During operation, when the noise is harsh, the cover should be checked to eliminate the fault.

Working principle

When the screw conveyor is working, due to the gravity of the material and the friction force generated by the tank wall, the material can only move forward along the groove bottom of the conveyor under the push of the blade. It is the same as the translational motion of the rotating screw. The movement of the material in the intermediate bearing depends on the thrust of the material advancing behind it. Therefore, the transportation of materials in the conveyor is completely a sliding movement.

In order to make the screw shaft in a more favorable tension state, the drive device and the discharge port are generally placed at the same end of the conveyor, and the feed port is placed as close as possible to the tail of the other end. The rotating screw blade pushes the material for conveying, and the force that prevents the material from rotating with the screw conveyor blade is the weight of the material itself and the frictional resistance of the screw conveyor casing to the material.

According to the different conveying materials, there are solid surface, belt surface, blade surface and other types of blade surface type. The screw shaft of the screw conveyor has a thrust bearing at the end of the material moving direction to give the screw axial reaction force with the material. When the length of the machine is long, an intermediate hanging bearing should be added.

Technical Parameter

| Model | Steel pipe diameter (mm) | Pitch (mm) | Speed (r/min) | Delivery Volume (m³/s) |

|---|---|---|---|---|

| LS159 | 159 | 100 | 83 | 2-6 |

| LS219 | 219 | 175 | 83 | 5-12 |

| LS250 | 250 | 200 | 90 | 22 |

| LS315 | 315 | 250 | 70 | 36 |

| CLXB-250 | 18~25 | 50~70 | DN273 | 90-110 |

Related Products

Coarse, Fine, Ultrafine Powder Grinding Mills

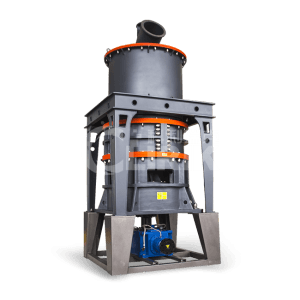

CLUM Ultrafine Powder Vertical Roller Mill

CLUM ultra-fine powder vertical roller mill is mainly suitable for the deep processing of ultra-fine and large-scale powder of non-metallic minerals such as calcite, marble, limestone, talc, barite, brucite, quicklime, gypsum, slag, phosphate, etc.

Capacity: 0.5-45t/h

Finished fineness: 200-3000 mesh

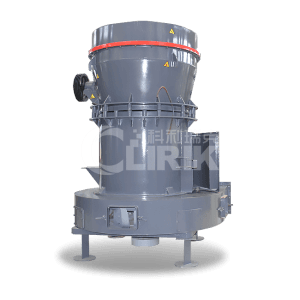

HGM Ultrafine Powder Grinding Mill

HGM Ultrafine Powder Grinding Mill also called ultrafine pulverizer, micro powder grinding mill, limestone grinding mill, calcium carbonate grinding mill. HGM ultrafine powder grinding mill is mainly suitable for superfine powder processing.

Capacity: 0.5-45t/h

Finished fineness: 100-3000 mesh

YGM Raymond Roller Grinding Mill

YGM Raymond roller grinding mill is mainly suitable for grinding and processing metallurgy, building materials, chemical industry, mining, and other mineral products.

Capacity: 1.5-40t/h

Finished fineness: 80-600 mesh