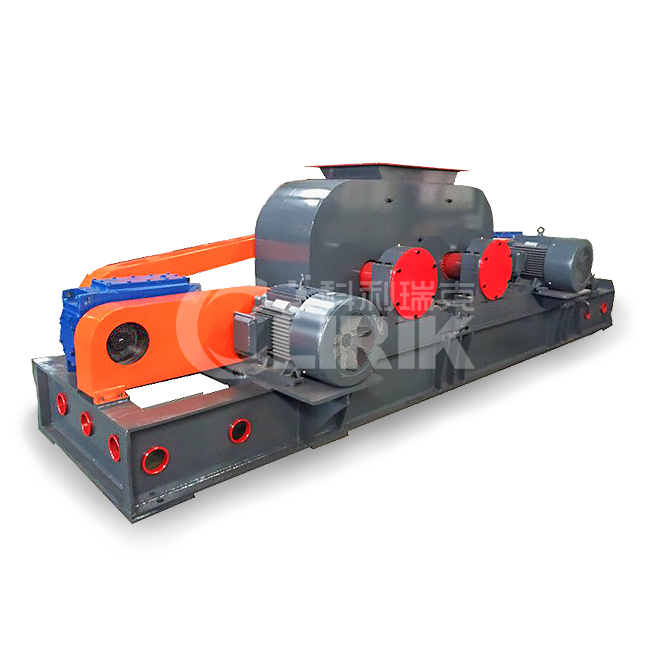

Shanghai Clirik Machinery Co.,Ltd. selects special alloy wear-resistant materials to build the core components of the equipment, and combines the design concept and process technology of the second-generation HGM ultrafine grinding mill to optimize equipment performance. Relying on the advantages of high efficiency and low energy, long life, environmental protection, and convenient maintenance, Clirik's HGM ultrafine grinding mill has become the best choice for powder applications in the chemical industry, paper industry, metallurgy industry, transportation industry, coating industry, and PVC industry.

Equipment Upgrade

Roller upgrade

The diameter of the upper two layers of grinding rollers is increased, which can process coarse particles. The lower two layers of grinding rollers are precisely adjusted to efficiently grind fine powder, which greatly improves the grinding capacity of the entire main machine.

Powder separator upgrade

The power of the classifier is increased by 67%, and the diameter of the impeller is increased by 45%, which greatly improves the overall classifier efficiency.

Host motor upgrade

With the increase in motor power, the equipment production capacity has been increased by about 25% when the power consumption is the same as the previous generation, making the equipment high efficiency and low energy.

Reducer upgrade

The reducer is upgraded to No. 11. The torque of this model is increased, the main machine grinding is more stable, and the equipment is more reliable and durable.

Dust collector upgrade

Increase the dust removal pipeline to increase the air flow; the area of the filter bag increases by 36%, which increases the filtration efficiency of the entire dust collector by about 40%.

Fan upgrade

The increase in fan power greatly increases equipment production capacity, while also enhancing the equipment's environmental protection and dust removal capabilities.

Equipment summary

Compared with the previous generation equipment, the grinding efficiency and fine powder content of the upgraded third-generation HGM ultrafine grinding mill have been significantly improved. In order to cope with increasingly stringent environmental regulations, the third-generation HGM ultrafine grinding mill optimizes the fan power and increases the number of dust filter bags, making the third-generation HGM ultrafine grinding mill's environmental protection and dust removal capacity reach a new height. Whether it is equipment performance or the stability of the finished product, the third-generation HGM ultrafine grinding mill can be called the leader in the field of mineral powder grinding equipment.

If you want to know the Third Generation HGM Ultrafine Grinding Mill or have any questions about Raymond mill, please do not hesitate to contact us.

Phone: 008613917147829/0086-21-20236178

E-mail: info@clirik.com

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201,China.