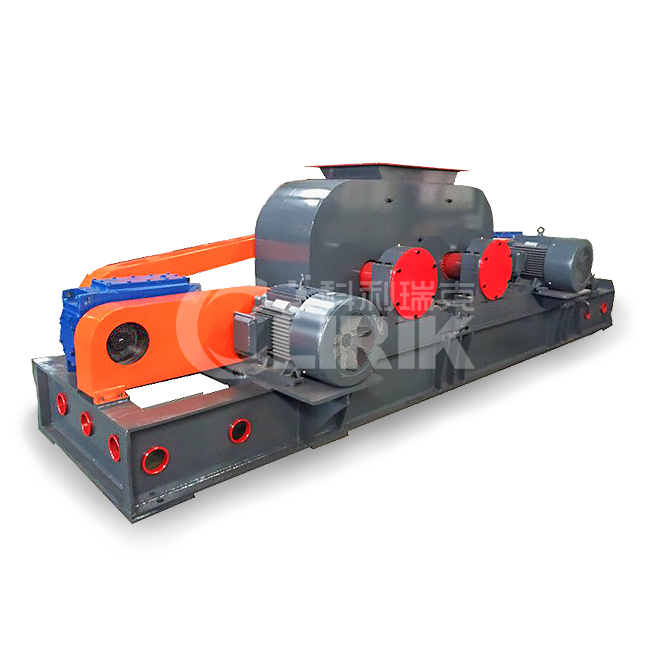

What Machine is Suitable for Micro Powder Processing? Here we'd like to introduce something about it for you.

Micro Powder Grinding mill,Micro Powder Grinding Plant:

Usually,the micro powder grinding plant is suitable to porcess the raw material to the granularity of 325-2500 meshes, and the final powder porduct granlularity is among 0.044-0.0055mm. Mico means very small and tiny ,it actually need very special equipment to process to that degree with special machine. If we are not going to process that kind of powder, the Coarse powder grinding plant is definitely enough to us, since it is more efficient than Miron Powder Grinding Plant and more economical, low cost, low powder consumption, which are the advantages that the Micro powder grinding plant can never have.

However, Coarse powder grinding plant is coarse powder grinding plant after all. This machine can not make micron powder but the micro powder grinding plant is able to process the micron powder with ease but without any hitch. Compare to other micron powder grindind plant, this mirco powder grinding plant produced by Clirik has stable and high efficiency. Furthermore, Under the same condition of finished final size of the powder and the same motor power, the capacity of micron grinding plant produced by Clirik is twice as much as jet mill, mixing grinder and ball mill, what's more, the energy consumption decreased 30%.

Micro powder processing means more impact on the roller and ring, which requires wear-resisting materials in the grinding plant. Without the unique technique in forging these stuff, the micro powder grinding plant break downs easily and the service life span of this mathine will be short. The mirco powder grinding plant produced by Clirik takes in special alloy, applies yet most advanced German technology, hence that, under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3 times longer than impact mill or turbo mill.